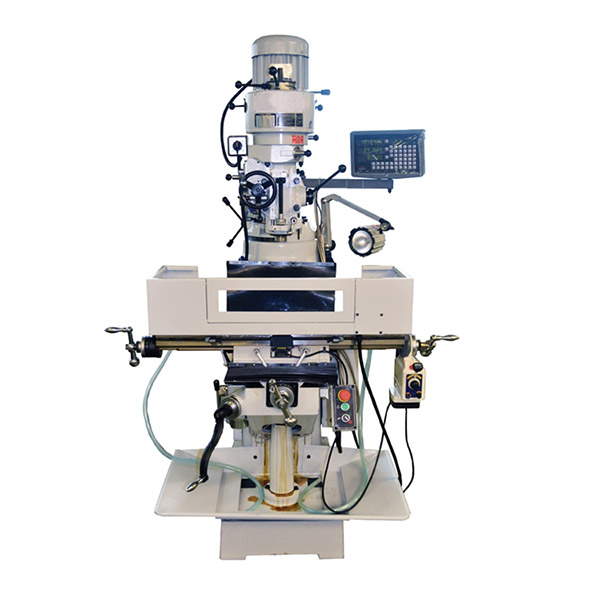

Wholesale Discount Manual Metal Lathe - DML6350Z drilling & milling machine – Falco

Wholesale Discount Manual Metal Lathe - DML6350Z drilling & milling machine – Falco Detail:

Product Features

1.can realize vertical, horizontal milling processing functions.

2.for vertical milling,spindle sleeve has two kinds of feed, manual and micro .

3.X, Y, Z three directions guideways has grinding function after super audio quenching .

4.automatic feed for X directions.

Standard Accessories

Milling chuck, Drawbar, Extension bar, Reduction sleeve, Machine vice, Wrench, English operation manual, X axis power feeder, main spindle power feeder

Specifications

| Specification |

Unit |

DML6350Z |

| Spindle taper |

MT4/ISO40/ISO30/R8 |

|

| Max.driiling diameter |

mm |

50,30 |

| Spindle travel |

mm |

120 |

| Sleeve feed |

mm/min |

0.08/0.15/0.25 |

| Distance form vertical spindle to column |

mm |

200~500 |

| Distance form vertical spindle to table |

mm |

120~480 |

| Distance form horizontal spindle to table |

mm |

0~360 |

| Distance form horizontal spindle to arm |

mm |

175 |

| Spindle speed range |

r/min |

60~1500/8(vertical);40~1300/12(horizontal) |

| Table size |

mm |

1120X280 |

| Table travel Range of longitudinal,cross travel |

mm |

600×250×360 |

| Table feeds range(x/y) |

12~370/(MAX.540) |

|

| T of table (NO./WIDTH/DISTANCE) |

w |

3/14/63 |

| Main motor |

kw |

1.5(vertical)2.2(horizontal) |

| Motor of table power feed |

w |

370 |

| Up/down motor of headstock |

w |

|

| Coolant pump motor |

w |

40 |

| Speed of coolant pumps |

12 |

|

| Overall dimension |

mm |

1660×1340×2130 |

| N.W./G.W. |

kg |

1250/1400 |

Product detail pictures:

Related Product Guide:

We thinks what clients think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater quality, lessen processing costs, price ranges are much more reasonable, won the new and outdated shoppers the support and affirmation for Wholesale Discount Manual Metal Lathe - DML6350Z drilling & milling machine – Falco , The product will supply to all over the world, such as: Los Angeles, Sri Lanka, Libya, We've customers from more than 20 countries and our reputation has been recognized by our esteemed customers. Never-ending improvement and striving for 0% deficiency are our two main quality policies. Ought to you want anything, don't hesitate to contact us.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.