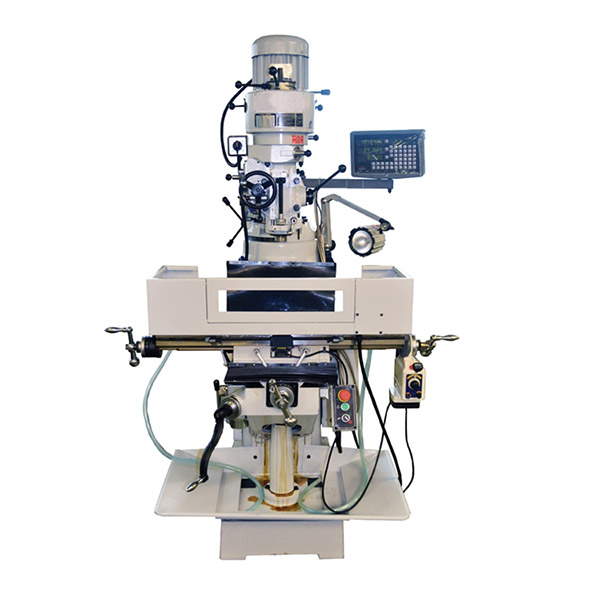

VMC850B CNC Milling machine, vertical machine center – Falco

VMC850B CNC Milling machine, vertical machine center – Falco Detail:

Product Features

High-speed /high precision three axies feed structure

X, Y, Z three axies all adopt precise linear rolling guide rail (THK or HIWI)

Less noise, low resistance, high speed, high precision

Three axies all adopt C3 degree high precision ball screw, fix the poles of ball screw and pre pull, and optimize drive rgidity reduce the heat distortion

The poles of ball screw adopt the NSK high -precision angle of contact ball screw bearing

High-speed /high-precision spindle

High rigidity, high precision, big hole diameter spindle design, adopt the precise slide angle ball bearing (P4 degree) support

High rotary spindle provides high-speed cutting for customers, ensure the long term stabilization of machine tool’s precision

The spindle adopts synchronous belt drive of big torsion, no friction and less noise

Main Configuration

Automatic Pump: Herg ,1pcs , Japan

Manual air gun : 1pcs

Manual pulse generator: 1pcs ,from Taiwang

Alarm light in three colors :1pcs

Work lamp :1pcs

Spindle Motor: 1pcs,Fanuc

Spindle : 1pcs,Posa ,Taiwang

BK3 Coupling: 3pcs,R+W from Germany

Synchronous wheel : 1pcs,Posa, Taiwang

Synchronous belt: 1pcs ,Posa,Taiwang

Ball screw: C3 class ,4012,Posa, TAIWANG or THK , JAPAN

3axle Balling (roller)Bearing: 6sets/12pcs , NSK , JAPAN

Precision Locked nuts: 6pcs

Balance block: 1pcs

Balance chains: 12A -1*79

Specifications

| worktable size | mm |

1000×500 |

| t-slot size | mm |

18×5 |

| max load on table | kg |

600 |

| x axis travel | mm |

850 |

| y axis travel | mm |

560 |

| z axis travel | mm |

650 |

| spindle taper |

7/24 bt40 |

|

| spindle speed | r/min |

8000 |

| main motor power | kw |

11 |

| x/y/z rapid travel | m/min |

32/32/30 |

| feed speed | m/min |

20 |

| tool magazine form |

disc type with arm |

|

| tool quantity | piece |

24 |

| tool change time | s |

2.5 |

| general power capacity | Kva |

25 |

| overall dimensions(l x w x h) | mm |

4400x2565x2944 |

| weight of machine | Kg |

6800 |

Product detail pictures:

Related Product Guide:

Our corporation insists all along the quality policy of "product top quality is base of organization survival; purchaser pleasure will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" plus the consistent purpose of "reputation very first, purchaser first" for VMC850B CNC Milling machine, vertical machine center – Falco , The product will supply to all over the world, such as: Seychelles, Seattle, Albania, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Let us join hands to create a brilliant tomorrow! We are looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to provide you with high quality and efficient services.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.