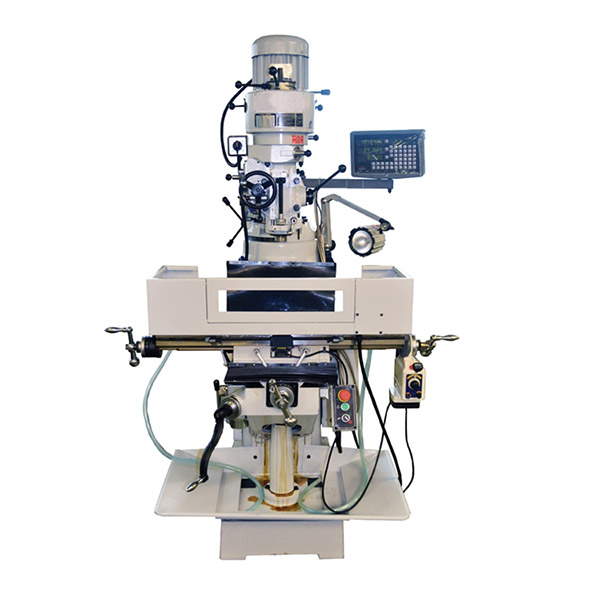

Special Design for Cylinder Head Surface Grinding Machine - Surface Grinding Machine KGS1632SD With Dense Magnetic Chuck – Falco

Special Design for Cylinder Head Surface Grinding Machine - Surface Grinding Machine KGS1632SD With Dense Magnetic Chuck – Falco Detail:

Standard Accessories

|

1 |

Grinding wheel |

2 |

Wheel flange |

|

3 |

Wheel balancing base |

4 |

Wheel balancing arbor |

|

5 |

Extractor |

6 |

Diamond dresser |

|

7 |

Leveling pad |

8 |

Anchor bolt |

|

9 |

Tool box with tools |

10 |

Dense electric magnetic chuck |

|

11 |

Cooling system |

12 |

Working light |

Features

1. Well designed cast iron structure provides excellent dampening

2. Flange mount spindle cartridge for superior side grinding rigidity

3. Grinding spindle features low-maintenance preloaded high precision angular ball bearings(NSK P4 grade)

4. “V” and flat type guide way which precision hand scrapped turcite saddle ways for smooth and long lasting performance

5. Table guideways are hardened, ground and counter-laminated with PTFE(TEFLON) to ensure high wear-resistance

6. Centralized automatic lubrication system ,supplies oil to guide-ways and lead-screws as the machine operates. This system ensures all the critical components are lubricated with the right amount of oil at all times

7. Separate hydraulic tank prevents heat and vibrations from being transferred to the machine

8. Electric components and functional modules are well arranged and packed in the electric cabinet, making maintenance and trouble-shooting easily accessible

9. Magnetic force can be adjusted

10. Safety 24V control circuit power

Specifications

| Parameters |

Unit |

KGS1632SD |

|

| Working Surface of Table |

mm |

400×800 (16″×32″) |

|

| Max.Table Travel |

mm |

850 |

|

| Max.Cross Travel |

mm |

440 |

|

| Distance Between Table Surface and Spindle Center |

mm |

580 |

|

| Max.Table Load |

kgs |

700 |

|

| T-Solt (Number×Width) |

mm |

3×14 |

|

| Table Speed |

m/min |

5~25 |

|

| Cross feed Handwheel |

1gard |

mm |

0.02 |

|

1 rev |

|

5 |

|

| Automatic Cross feed of Saddle |

mm |

0.5~12 |

|

| Power Cross Feed |

50HZ |

mm/min |

790 |

|

60HZ |

|

950 |

|

| Grinding Wheel Dimensions |

mm |

355×40×127 |

|

| Spindle Speed |

50HZ |

rpm |

1450 |

|

60HZ |

|

1740 |

|

| Vertical Handwheel |

1gard |

mm |

0.001 |

|

1 rev |

|

0.1 |

|

| Automatic Down Feed Rate |

mm |

0.001~1 |

|

| Power Head Increment |

mm/min |

210 |

|

| Spindle Motor |

kw |

5.5 |

|

| Vertical Motor |

w |

1000 |

|

| Hydraulic Motor |

kw |

2.2 |

|

| Dust Collection Motor |

w |

550 |

|

| Coolant Motor |

w |

90 |

|

| Crossfeed Motor |

w |

90 |

|

| Floor Space |

mm |

3600×2600 |

|

| Packing Dimensions |

mm |

2790×2255×2195 |

|

| Net Weight |

kgs |

2850 |

|

| Gross Weight |

kgs |

3150 |

|

Product detail pictures:

Related Product Guide:

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Special Design for Cylinder Head Surface Grinding Machine - Surface Grinding Machine KGS1632SD With Dense Magnetic Chuck – Falco , The product will supply to all over the world, such as: Haiti, Kenya, UAE, We hope to have long-term cooperation relationships with our clients. If you are interested in any of our products, make sure you do not hesitate to send enquiry to us/company name. We ensure that you can be totally satisfied with our best solutions!

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!