Popular Design for 5 Axis Machining Center - Single Column X4020HD Plano Milling Machine – Falco

Popular Design for 5 Axis Machining Center - Single Column X4020HD Plano Milling Machine – Falco Detail:

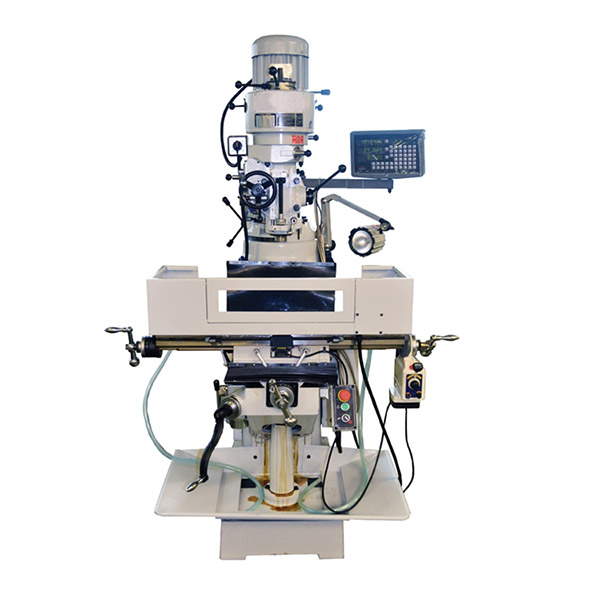

Optional

Guide rail shield (stainless iron)

Column beam shield (organ protection)

CE Schneider electrical components

3 axis DRO

Features

Core technique originates from Taiwan, scientific & logical design of the structure and adoption of the advanced function unit can realize strong cutting function, high working efficiency, safe & reliable movement and long working life.

1. Heat-treatment technics & mechanical lubrication are adopted on the guideway of the machine body to reduce friction & prolong working life of the machine.

2. Stepless table speed change.

3. Rectangular or flat-V bed guideways, rigid machine bed/beam/column ensure stability of the machine in strong cutting.

4. Milling head can move vertically/horizontally or swivel ±30°.

It is used in machining, moulding and some other industries, especially the machining of plane/end face/inclined plane/T slot/ combined guideway of large/medium/small machine parts.

Brief Introduction

This Mini Excavator delivers power and performance in a compact size to help you work in the tightest applications. Its ability to fit through a narrow doorway makes it an excellent machine for indoor demolition work.

Structural features

High rigid gantry is an upgraded product of ZTE vertical machining center.

Tool magazine and spindle compound, tool change speed block.

Rigidity and life improvement.

Taiwan ball screw is equipped on the bed forward and backward, beam up and down, end milling head up and down, driven by servo motor.

Equipped with synchronous belt and synchronous wheel.

Hand held electronic hand wheel unit, convenient for three-axis tool setting.

Specifications

|

unit |

X2010*2m |

X4020 |

|

|

Working area |

|||

|

X axis travel |

mm |

2000 |

4000 |

|

Y axis travel |

mm |

2000 |

|

|

Z axis travel |

mm |

500 |

|

|

Beam movable distance (up and down) |

|

1200 |

|

|

Table dimensions |

mm |

2000×1000 |

4000×1600 |

|

T-slots(number*width*spacing) |

mm |

7×22×125 |

|

|

Spindle nose-to-table distance |

mm |

200—1200 |

|

|

Table load capacity (max.) |

kg |

2000 |

10000 |

|

Feed |

|||

|

X axis rapid feed |

mm/min |

2500 |

|

|

Y axis rapid feed |

mm/min |

2500 |

|

|

Specifications portamill |

|||

|

Z axis rapid feed (Gantry) |

mm/min |

430 |

|

|

Z axis rapid feed (cutter head) |

mm/min |

280 |

|

|

Work feed X axis |

mm/min |

0—1000 |

|

|

Work feed on Y axis |

mm/min |

0-1000 |

|

|

Headstock |

|||

|

Speed range |

rpm |

66-666(9级) |

|

|

Torque (max.) |

Nm |

790 |

|

|

Spindle mount |

|

ISO 50 |

|

|

Head swivel range |

|

±35° |

|

|

Drive capacities |

|||

|

Motor rating-headstock |

kW |

15 |

|

|

X axis |

kW |

4 |

|

|

Y axis |

kW |

3 |

|

|

Z axis |

W |

400 |

|

|

Dimensions / weight |

|||

|

Dimensions |

mm |

5400×3000×2500 |

|

|

Weight |

kg |

11000 |

|

Product detail pictures:

Related Product Guide:

No matter new buyer or old purchaser, We believe in long expression and trusted relationship for Popular Design for 5 Axis Machining Center - Single Column X4020HD Plano Milling Machine – Falco , The product will supply to all over the world, such as: Holland, Johannesburg, Ukraine, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality products and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.