Q: what’s the difference between shrink tube expansion and shrinkless tube expansion ?

A:

The difference between the shrink tube expansion and shrinkless tube expansion processes in heat exchangers is significant in terms of principles and applications.

Shrink tube expansion

The shrink tube expansion process is a common mechanical manufacturing technique. During tube expansion, the diameter of the copper tube increases due to the larger size of the expansion ball compared to the inner diameter of the tube, resulting in tighter contact with the fins and improved heat transfer efficiency of the heat exchanger. However, this type of tube expansion causes an increase in the cross-sectional area of the copper tube, leading to a reduction in the length of the tube, known as the copper tube shrinkage rate. For example, in the air conditioning industry, the shrinkage rate of internally threaded copper tubes is typically 3%-4%.

Shrinkless tube expansion

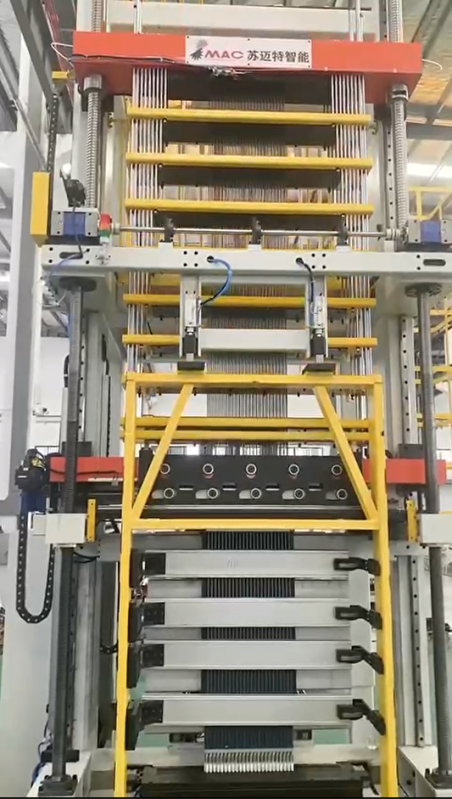

The shrinkless tube expansion process is a forced tube expansion technique. It compensates for the increase in the inner diameter of the copper tube by increasing the wall thickness, ensuring that there is no shrinkage in the length of the copper tube after tube expansion. This process requires the use of a special fixture on a tube expanding machine to clamp the tube ends and Hairpin-tube bottoms of the heat exchanger components before tube expansion. After shrinkless tube expansion, changes occur in the inner diameter and thread parameters of the copper tube, necessitating validation of the heat exchange performance, system pressure, and long-term operation of the heat exchanger. In addition, some designs of shrinkless tube expansion include internal ribs that apply tensile force to the tube body during the expansion process, preventing tube shrinkage and ensuring uniform tube expansion for improved heat conduction.

In summary, the main difference between shrink and shrinkless tube expansion processes lies in whether the copper tube shrinks after expansion and how the design of the process can optimize the performance of the heat exchanger. The specific choice of process depends on the specific application requirements and process conditions.

Post time: Feb-05-2024