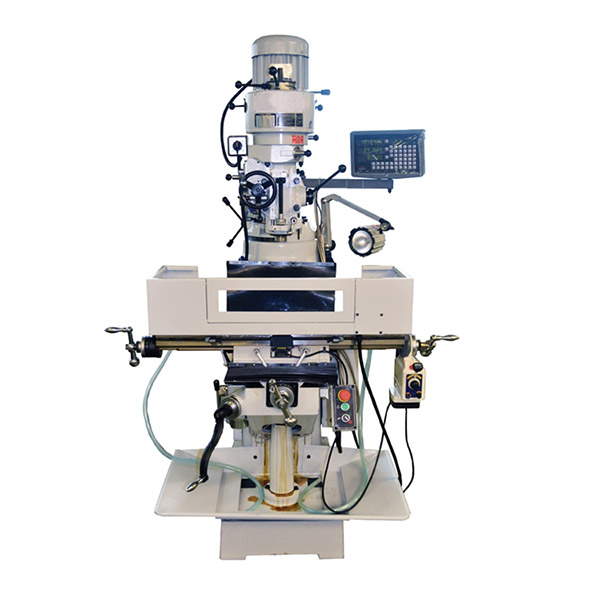

Factory Cheap 5 Axis Cnc Milling Machine - TM6325A vertical turret milling machine, with TF wearable material – Falco

Factory Cheap 5 Axis Cnc Milling Machine - TM6325A vertical turret milling machine, with TF wearable material – Falco Detail:

Product Features

① Increased Productivity, mill efficiently and effectively

② Bolthole Calculations, calculate bolthole patterns instantly

③ Tool Offsets and Tool Library

④ Jog Control, move quickly from one location to another- using one axis at a time or any two axes simultaneously

⑤ 3-D Contouring, ability to import and run G-code files from CAD/CAM programs

⑥ Mirror/Repeat/Rotate, easily manipulate part programs to save time and reduce program steps.

⑦ 10″ flat panel, vivid, color, LCD display to view immediate graphic feedback

Standard With

1. Draw Bar

3. Tools Box and Tools

5. Working Lamp

2. Electric Cabinet

4. Manual Oil Pump

6. ISO40 spindle taper

Specifications

|

Model |

TM6325A |

|

Table size |

254×1270/1370 |

|

Longitudinal travel |

800/900 |

|

Cross travel |

400 |

|

Vertical travel |

405 |

|

T-slot |

3*16 |

|

Ram travel |

550 |

|

Distance from spindle nose to table |

0-428 |

|

Spindle taper |

R8 |

|

Spindle travel |

127 |

|

Spindle speed |

Standard:16 steps: 50HZ 65-4500rpm, 60HZ:80-5440rpm |

Introduction

Double 550 swallowtail guideway is adopted on both Y and Z-axis, so it is easy to adjust. The guideway on saddle is lined with TF wearable material.

Rectangular guideway is adopted both on Y, Z-axes. The guideway on saddle is lined with TF wearable material, which makes the machine stably and rigidly,also makes it beautiful and easy to operate.

Characteristic

●550 swallowtail guildeway is adopted on Z-axis, and rectangular guideway on Y-axis.

●Adopted strengthen rib on both sides of the columb, that makes the machine rigidly and beautiful.

●Fixed structure is used to conned the mill head without ram, which makes the cut intensity well.

●Rectangular guideway on Y, Z-axis makes the machine stable and rigidly. Guideway with TF wearable material.

Product detail pictures:

Related Product Guide:

We believe that long expression partnership is often a result of top of the range, value added service, prosperous encounter and personal contact for Factory Cheap 5 Axis Cnc Milling Machine - TM6325A vertical turret milling machine, with TF wearable material – Falco , The product will supply to all over the world, such as: Lesotho, Hongkong, Karachi, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our goods. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for you personally always.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.